My Room is Full of Glass

How overwhelming

LANGSTON’S PREVIOUS MISSIVE FULL OF WHIMSY AND INVENTIVENESS!!!!

For the last five years, I’ve been making lamps, planters, and other home goods from recycled bottles and selling them on Etsy.

I make everything by hand in the basement of my1 apartment in Brooklyn.

The apartment is tough to fully capture with an image, so I bought a drone on Temu to get this dynamic and expressive shot:

This was the end of the drone functioning, but only the beginning of me being pissed about it.

Here is the primary inside view of the shop.

I built the whole thing as quickly as possible with the cheapest materials available. For example, instead of using plywood (relatively inexpensive), I used OSB (incredibly inexpensive). It’s inferior to plywood in every way, except that it’s more bendy, and that’s a bad thing.

Now a quick overview of how I make my top-selling lamp. I recorded this last August to try to get an Etsy Design Award from Drew Barrymore, so I really have my “Drew” voice on:

Since then, I’ve made countless improvements. I’ll use this time to talk about them too much:

On the far right of the main workstation is the Bottle Processing Center, where the bottles are processed:

1. THE CUTTER

The Cutter is in the middle because it’s the star. It’s the first machine I built for glass, and without it the other two would be useless. A motor spins a diamond-crusted blade at 10,000 rpm to grind away glass with clean, unbroken edges.

I set the height using the controls.

Turn on the coolant water

And cut the bottles.

This is the fourth version of the Cutter. The only original part that’s still left is the bucket.

To use this first version, I had to bend over double and grab the bottles from the top. The towel lining in that box is the first towel I ever purchased for myself, of my own volition.

You always need to have water on glass when you’re cutting it. The water helps cool and prevent chipping, and also limits dust so that you don’t get Miner's phthisis2.

For the first few years, I cut the bottles fully submerged in water. This kept any little shards of glass from spraying all over my only room that I slept in.

Eventually I’d end up with a bucket full of rancid glass water and dump it down a nameless drain in the backyard.

Later, I moved to an apartment without an anonymous drain, and had to set up a hose system that filtered out big chunks of glass and vomited the water into our toilet.

During this era, if I cut glass for more than a few continuous minutes, my cheap tool would overheat and make the whole room smell like plastic. To give the tool time to chill out, I started hanging it out the window in a tote bag.

This bedroom was crazy.

Read more about it here:

It has long been a production dream to add a keypad to the Cutter and have it move automatically to specified cutting heights. But time is so slippery.

THE SANDER

The next machine is the sander, which removes rough edges from the inside and outside edges of the glass. There’s a lot to say about it but I keep getting these notifications.

So I’ll just quickly show you how it works:

THE WASHER

The third and newest glass machine is the Washer. It washes.

I used to wash the finished glass parts by hand in buckets, but scrubbing them kept creating scratches, so I decided to blast the muck off of them with high-pressure water.

I finished the Washer yesterday evening so that it could be displayed in this article, which I had not yet written. Every new machine is a fresh ordeal.

There are all these hoses, and valves, and pumps and they do different things for different reasons, and honestly I’m so sick of thinking about it.

It leaks rather violently from the top at the moment, but only because it’s trying so hard to wash the shit out of glass.

It keeps spraying water on all of my computers.

Luckily, I found them all in the trash, so the stakes are inherently low. Adding a thicker lid should fix the problem.

Regrettably, I don’t have time in this article to talk about the drilling station,

Gluing Station,

Tumbling Station,

or the Lathe.

They’re all fascinating, though. Especially to me. And aren’t we all me, in a way?

Let’s Check In

Wow, you might be starting to think, making home goods from repurposed glass in your basement in Brooklyn seems like an awful lot of work. Why didn’t you choose almost ANY other path?

Ultimately, I am obsessed with extracting utility from garbage. Utility is all around us, and so often squandered.

Here’s a video from the 2023 WNBA Finals. Great game.

On the way out I picked up every discarded promotional towel I could find.

In the years since, I’ve used them for countless projects.

Every time I use one, I get a little bit of satisfaction that stretches all the way back to that game.

Which brings to mind another critical point:

A stranger’s towel from a WNBA game that I’ve saved for two years is inherently more VALUABLE than a higher-quality towel that I could buy conveniently right when I need it. Because it has HISTORY. If I keep one of the towels for twenty! years, it will have even MORE value. Objects accumulate value.

Ahh, we’re going way off the rails here. I need to sell glass stuff, I’m writing this to sell glass stuff.

In 2020 I started collecting Grady’s Cold Brew bottles3 because I found them aesthetic, and they were trash, but trash isn’t garbage, etc, etc.

Once I had about 20 of them, people started pressing me about why I saved them, what I would do with them, and if I could take them out of the shared spaces in the apartment. I could have thrown them away, but they had already accumulated value. So I spent five years developing a justification for having them.

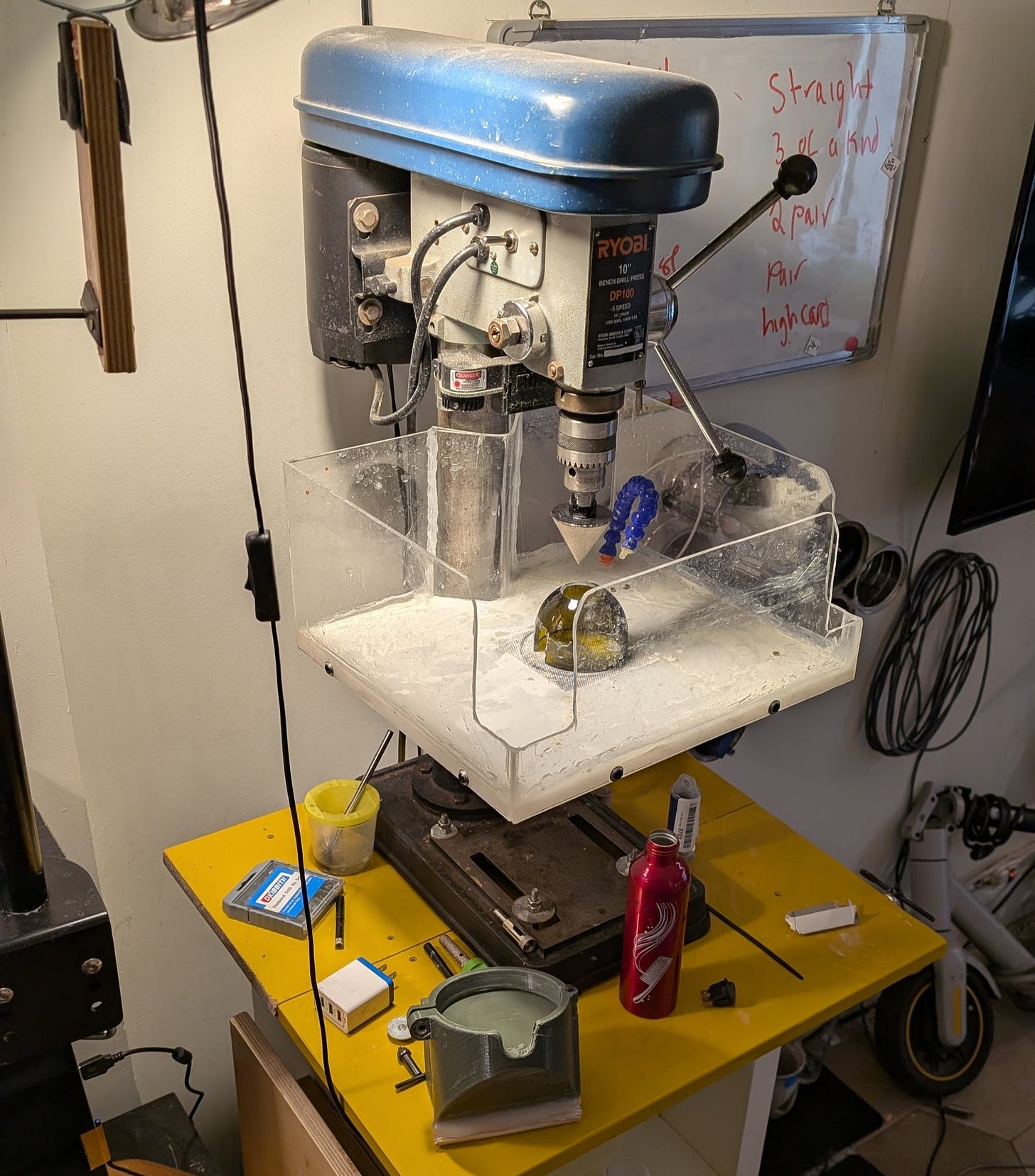

A brief, but relevant, aside: here’s a machine I made to drill holes in glass.

I’m not going to bother to explain why I built it this way. It leaked, it didn’t work well, and I found its appearance vulgar.

I turned it sideways and it stopped leaking but still vibrated too much and chipped glass.

Then I redid the WHOLE thing and it still didn’t work.

So I built it AGAIN and really made it shiny and nice but it still shook around too much and drilled bad holes.

Finally, I just bought a big drill press for $50 from a really sweet guy named Lance and it worked perfectly right away.

This is the hidden danger of attempting to extract utility from garbage. I should have accepted after the first version of this machine that some trash just can't be utilized.

Some trash is just trash.

Although I do still have it, obviously. I spent so much time on it! Gotta be able to use it for something.

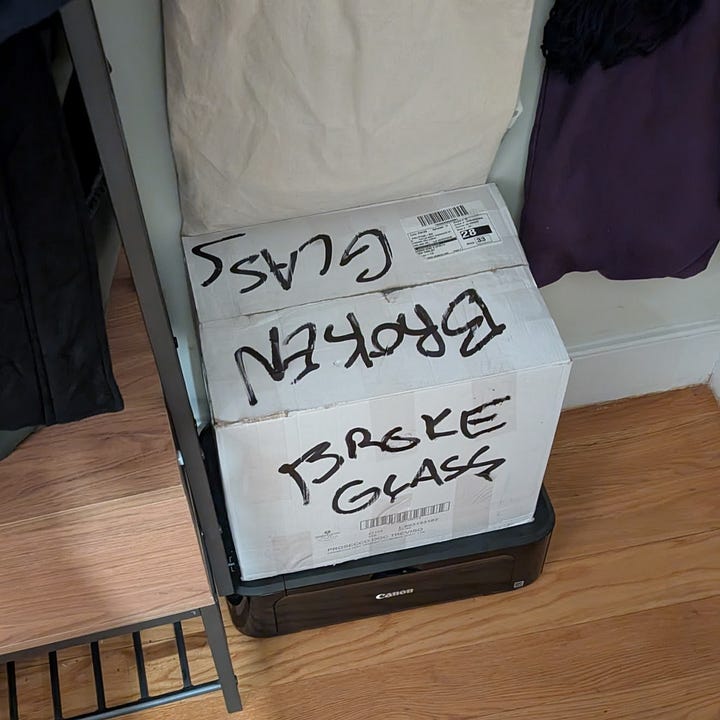

Look, I’ve broken a lot of glass to get here.

But there are still so many things I need to do.

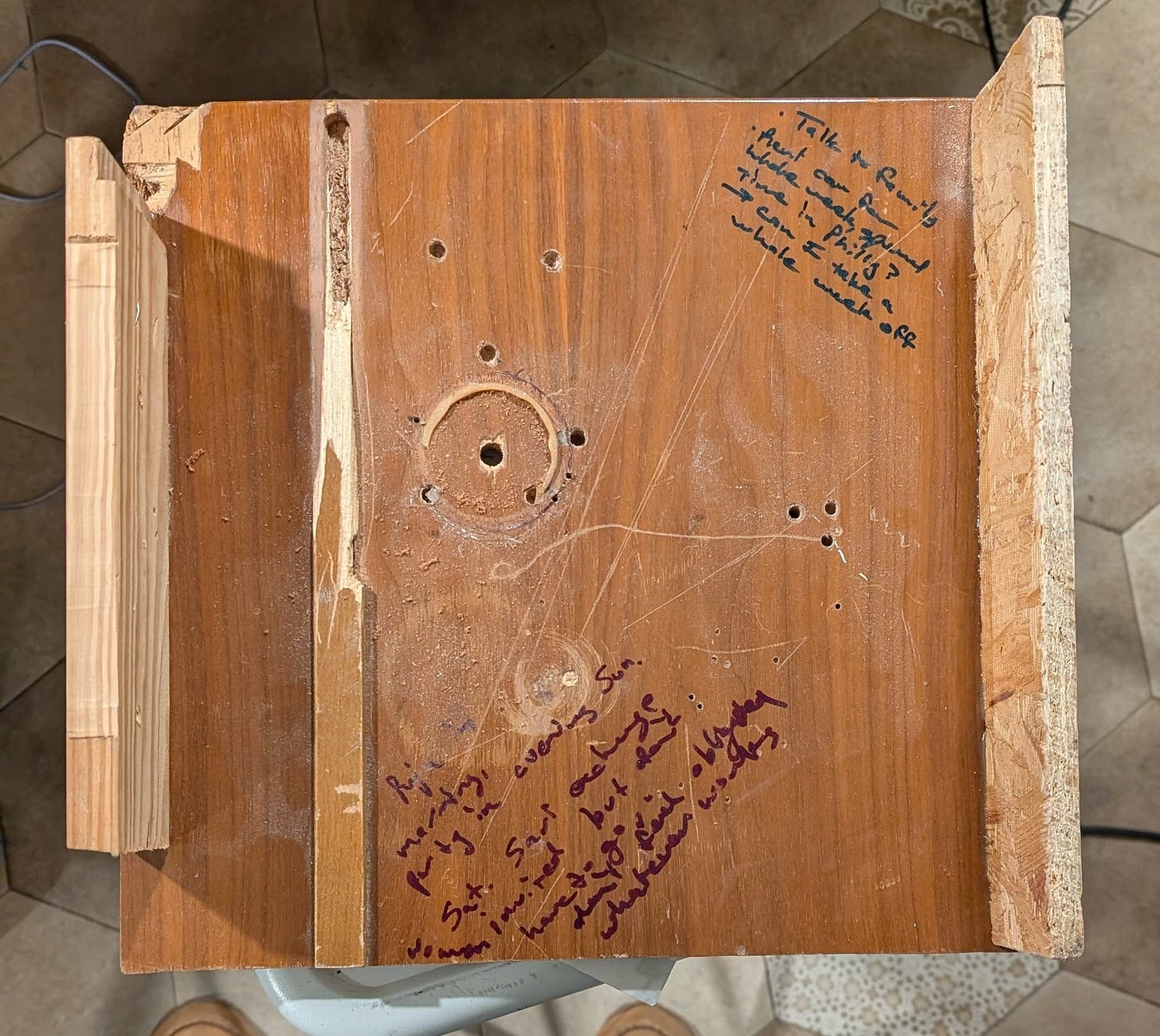

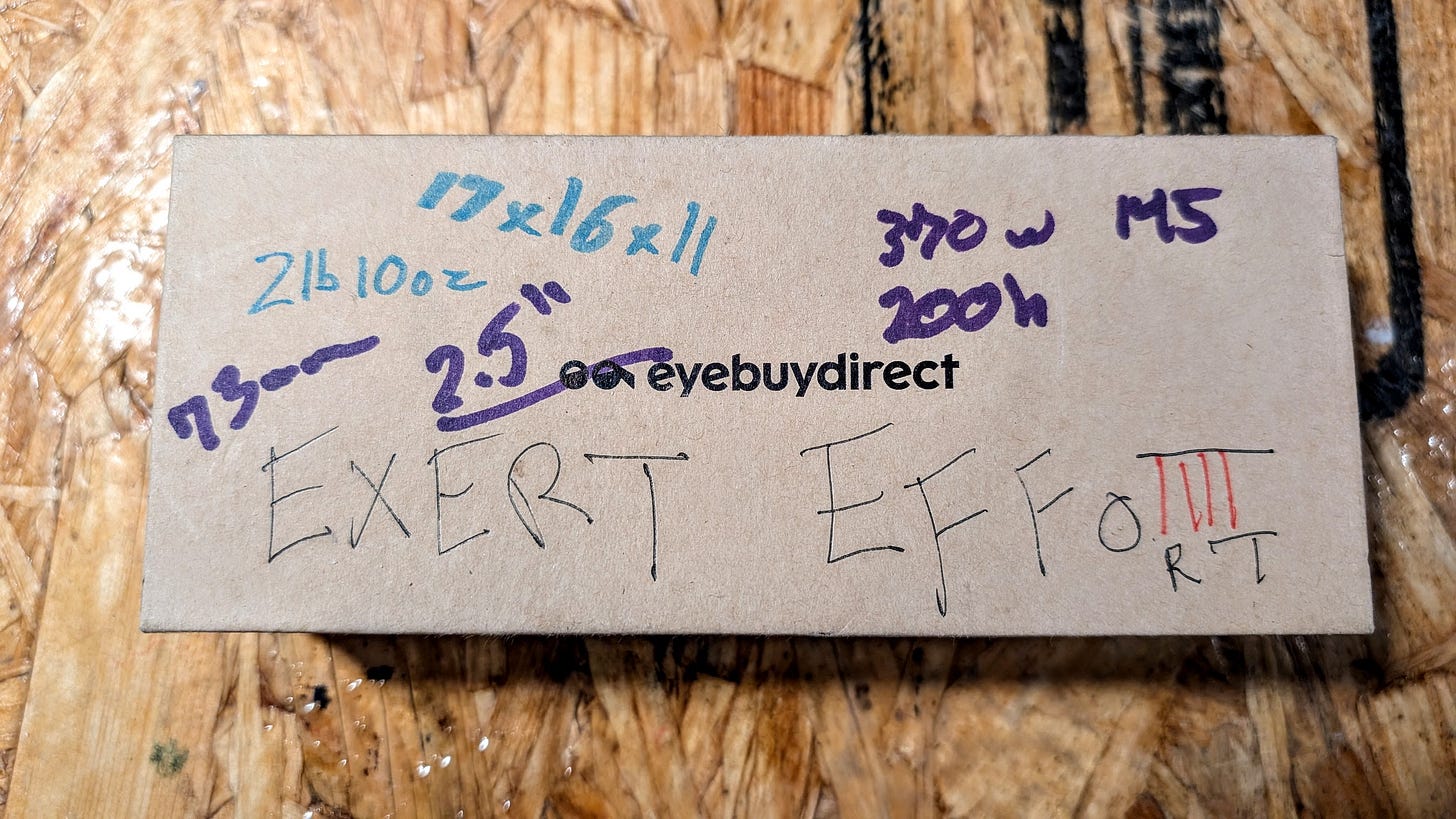

It’s hard to keep track of, because most of my notes are on random pieces of wood.

And some notes are more conceptual, which is challenging to interpret when I go back to try to complete them.

But other notes make sense every single time.

Follow me @MACDTL everywhere to continue the journey.

Ritam’s Footnote

(Smiling approvingly, happy, proud) Damn, bitch, you live like this?

Nabeel’s Footnote

Grady’s Cold Brew would be the cold brew I would drink if I drank cold brew. They have the most tasteful branding, and something about it seems old fashioned and cool. Just my two cents. Pretty fun that we can just call in a ringer like this to put out a banger when we don’t have the juice. Which other Substacks can do that…

Technically the top floor is “my fiance’s”

It’s mostly called “silicosis” but I thought this was the coolest nom-de-plume.

Shout-out to Grady’s they give me empty bottles now

🔥 🔥 🔥